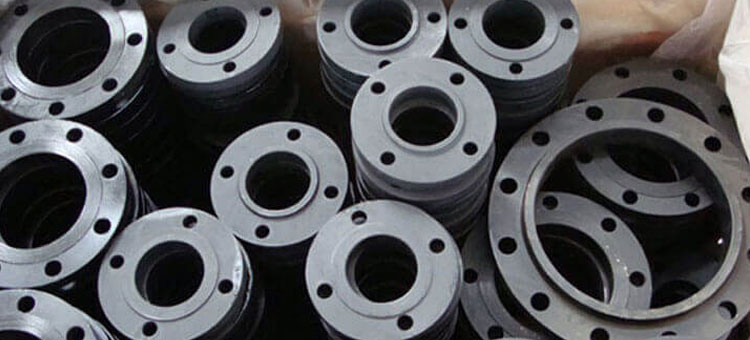

Carbon Steel Forged Flanges Manufacturer, Supplier, Exporter & Stockist in india

Carbon steel forged flanges are essential components in piping systems, used for connecting pipes, valves, and equipment in various industries. These flanges are typically manufactured from carbon steel, which is chosen for its durability and cost-effectiveness. The exact specifications of carbon steel forged flanges can vary widely depending on the application, size, and pressure requirements. Size Range and Pressure Ratings: Carbon steel forged flanges are available in a wide range of sizes, typically ranging from as small as 1/2" to 48" or even larger. The pressure ratings of these flanges are determined by industry standards such as ANSI/ASME B16.5, B16.47, B16.36, API 6A, MSS SP-44, and others. These standards specify the flange dimensions and pressure-temperature ratings to ensure compatibility and safety in various operating conditions.

Facing Type and Flange Material Grade: Flanges come with different facing types, including Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ), and others, which serve specific sealing purposes. The choice of flange material grade is crucial and depends on factors such as the corrosiveness of the environment and the required strength. Common material grades include ASTM A105, A350 LF2, A694 F65, among others. Flange Standards and Types: Carbon steel forged flanges are manufactured to adhere to industry standards like ANSI/ASME, API, MSS, DIN, EN, BS, JIS, GOST, etc. They are available in various types, including Weld Neck (WN), Slip-On (SO), Blind (BL), Socket Weld (SW), and more, each designed for specific applications.

Carbon Steel Forged Flanges Specification

| Specification | Common Values and Standards |

| Size Range | Typically from 1/2" to 48" or larger |

| Pressure Ratings | ANSI/ASME B16.5, B16.47, B16.36, API 6A, MSS SP-44, etc. |

| Facing Type | Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ), etc. |

| Flange Material Grade | ASTM A105, A350 LF2, A694 F65, etc. |

| Temperature Range | Varies depending on grade and application |

| Flange Standard | ANSI/ASME, API, MSS, DIN, EN, BS, JIS, GOST, etc. |

| Bolt Circle Diameter (BCD) | Determined by standard or customer requirements |

| Flange Face-to-Face Dimensions | Determined by standard or customer requirements |

| Flange Thickness (T) | Determined by standard or customer requirements |

| Flange Type | Weld Neck (WN), Slip-On (SO), Blind (BL), Socket Weld (SW), etc. |

| Coating/Finish | Black, Galvanized, or other corrosion-resistant coatings |

| Certification and Testing | Material certificates, NDT (Non-Destructive Testing), etc. |

| Application | Specific industry or project requirements |

Certification and Testing: To ensure the quality and integrity of carbon steel forged flanges, manufacturers provide material certificates and perform Non-Destructive Testing (NDT) as required. These measures ensure that the flanges meet the specified standards and safety standards for their intended application. Application: Carbon steel forged flanges find use in various industries, including petrochemical, oil and gas, chemical processing, power generation, and more. Their specifications are often tailored to meet the specific requirements of each industry or project, ensuring reliable and leak-free connections in critical systems. In summary, carbon steel forged flanges are versatile components that play a critical role in connecting and sealing pipes and equipment in various industrial settings. Their specifications, including size, pressure rating, material grade, and facing type, are chosen carefully to match the requirements of each application, ensuring the safe and efficient operation of piping systems.

Chemical Composition of Carbon Steel Forged Flanges

| Element | Carbon Steel Composition (%) |

| Carbon (C) | 0.05 - 2.0 |

| Manganese (Mn) | 0.3 - 2.0 |

| Silicon (Si) | 0.1 - 0.6 |

| Sulfur (S) | 0.05 - 0.3 |

| Phosphorus (P) | 0.05 - 0.3 |

| Iron (Fe) | Balance |

Mechanical Property of Carbon Steel Forged Flanges

| Property | Value |

| Tensile Strength | 485 MPa (70,300 psi) |

| Yield Strength | 250 MPa (36,250 psi) |

| Elongation | 22% |

| Hardness (Brinell) | 120 - 210 BHN |

| Impact Strength | Varies with temperature and grade |

| Modulus of Elasticity | 200 GPa (29,000 ksi) |

| Poisson's Ratio | 0.29 - 0.33 |

Applications & Uses of Pipe

- Used Automotive Industry

- Used in Oil and Gas Industry

- Used in Pulp & Paper Indusry

- Used in Constructions

- Used in Pharmaceuticals Industry

- Used in Refining Industry

- Used in Sugar Industries

We are Supplying Carbon Steel Pipe and Tube in below mentioned cities in India

Leading Carbon Steel Pipe and Tube Manufacturer, Supplier, and Stockist in India is Ryno Piping Solution Inc. due to the efficacy and dependability of its products. Each month, we deliver containers of carbon steel pipe and tube to Indian ports for a range of clients.

| Bengaluru | Mumbai | Chennai | Hyderabad | Kolkata | Pune |

| New Delhi | Ahmedabad | Jaipur | Surat | Salem | Gandhinagar |

| Bhiwandi | Tiruppur | Sivakasi | Jamnagar | Thiruvananthapuram | Rajahmundry |

| Bhubaneswar | Vijaywada | Firozabad | Agra | Rajkot | Bharuch |

| Panna | Raipur | Cochin | Ludhiana | Panipat | Durgapur |

| Peenya | Pimpri-Chinchwad | Channapatna | Kharagpur | Nashik | Indore |

| Varanasi | Haldia | Rourkela | Navi Mumbai | Moradabad | Noida |

Exporters of Carbon Steel Pipe and Tube

The United Arab Emirates, Europe, Africa, Asia, and all other continents are among the destinations for Ryno Piping Solution Inc.' exports of Carbon Steel Pipe and Tube. We export carbon steel pipe and tubes to a number of countries each month. As a result of our expanding customer base, we currently export two containers of carbon steel pipe and tubes to new locations and ports each month.

| Saudi Arabia | Qatar | Canada | Bangladesh |

| Oman | UAE | Venezuela | Turkey |

| Kuwait | Africa | United Kingdom | Singapore |

| Netherlands | China | Malaysia | Sri Lanka |